Ukuhlanganisa impushana yobisi nohlelo lokuxubha

Ukuhlanganiswa kwempushana yobisi kanye nomugqa wokukhiqiza we-batching

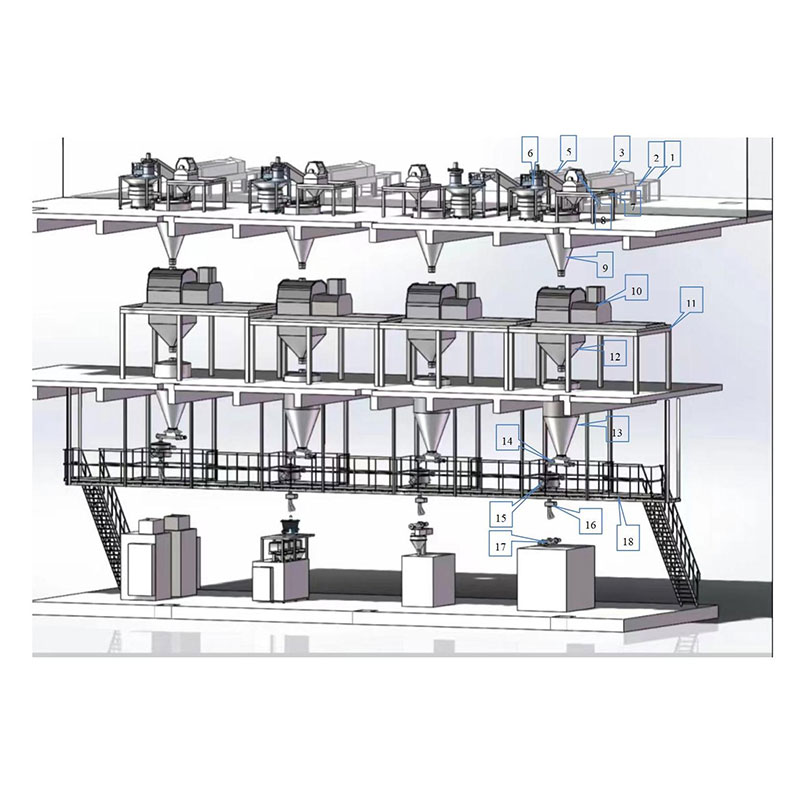

Ukuphakelwa kwezikhwama ngezandla (ukukhipha isikhwama sokupakisha sangaphandle)-- Isithuthi sebhande--Inzalo yesikhwama sangaphakathi--Ukuhambisa ukugibela--Ukusika isikhwama okuzenzakalelayo--Ezinye izinto ezixutshwe kusilinda ngesikhathi esifanayo--Imiksi yokudonsa--I-transition hopper--Isiviva-Isitoreji-Isilondolozi umtshina--Umshini wokupakisha

Ingakwazi Ukuhlanganisa Impushana Yobisi kanye Nenqubo Yokuhlanganisa

Isinyathelo sokuqala: Preprocessing

Ngoba ubisi olungaphekiwe lwendlela yokuxuba okomile lisebenzisa iphakethe elikhulu lempushana eyisisekelo (impushana eyisisekelo ibhekisela obisini lwenkomo noma ubisi lwembuzi kanye nemikhiqizo yalo egayiwe (whey powder, whey protein powder, skimmed milk powder, whole milk powder, njll.) njengezinto eziyinhloko zokusetshenziswa, ukwengeza ingxenye noma ukungangezi umsoco nezinye izinto ezisizayo, ukuvimbela ukukhiqizwa kobisi oluyimpushana ngokulandelana kokukhiqizwa kobisi izinto ezisetshenziswayo ngenxa yokungcoliswa kokupakishwa kwangaphandle ngesikhathi sokuxuba, kuyadingeka ukuhlanza izinto ezisetshenziswayo kulesi sigaba .Iphakeji yangaphandle iyacocwa futhi ihlutshiwe, futhi ukupakishwa kwangaphakathi kugezwa futhi kuhlanjululwe inzalo ngaphambi kokuthunyelwa kunqubo elandelayo.

Enqubweni yokucubungula, imisebenzi imi kanje:

- I-powder base-pack-pack enkulu eye yadlula ekuhlolweni ingaphansi kothuli lokuqala, ukucwecwa kokuqala, kanye nothuli lwesibili ngesinyathelo ngesinyathelo, bese ithunyelwa emhubheni ukuze inzalo futhi idluliselwe;

- Ngesikhathi esifanayo, izinto zokusetshenziswa ezifana nezithasiselo ezihlukahlukene kanye nezakhi ezilungele ukungezwa zithululwa futhi zithunyelwe emhubheni wokuvala inzalo ukuze kubulawe inzalo nokudluliselwa.

Isithombe esingezansi ukususwa kothuli nokusebenza inzalo kwephakeji yangaphandle ngaphambi kokucwecwa kwempushana eyisisekelo yephakheji elikhulu.

Isinyathelo sesibili: Ukuhlanganisa

- Inqubo yokuhlanganisa izinto ingeyenqubo yokuhlanza. Kudingeka izinyathelo eziqinile zokukhucululwa kwendle kanye nokubulala amagciwane kubasebenzi namathuluzi eshabhu, futhi indawo yokukhiqiza kufanele ibe nezidingo zepharamitha ezingashintshi, njengezinga lokushisa, umswakama, umfutho womoya, nokuhlanzeka.

- Mayelana nesilinganiso, izidingo ziphezulu kakhulu, phela zihlanganisa izindaba zokuqukethwe:

1.Amarekhodi afanelekile adinga ukusungulwa kukho konke ukukhiqiza nokusetshenziswa okuhlanganisiwe ukuze kuqinisekiswe ukulandeleka kolwazi lokukhiqiza umkhiqizo;

I-2.Ngaphambi kokuxubana, kuyadingeka ukuhlola uhlobo nesisindo sezinto ngokuvumelana nefomula ye-premixing ukuze kuqinisekiswe ukudla okunembile;

3. Amafomula wezinto ezibonakalayo njengamavithamini, izakhi zokulandelela noma ezinye izakhi zomsoco kufanele zifakwe futhi zilawulwe izisebenzi ezikhethekile zokuphatha ifomula, futhi izisebenzi ezifanele zizobuyekeza ifomula ukuze kuqinisekiswe ukuthi ukukalwa kwempahla kuyahambisana nezidingo zefomula.

4.Ngemva kokuqinisekisa ukuthi ukukala kwempahla kuyahambisana nezidingo zefomula, kuyadingeka ukuhlonza igama, ukucaciswa, usuku, njll. kokubalulekile ngemva kokuqedwa kokukala.

Phakathi nenqubo yonke yokuhlanganisa, izinyathelo zokusebenza zimi kanje

- Impushana yobisi eluhlaza ngemva kwesinyathelo sokuqala sokwelashwa nokuvala inzalo ingaphansi kokucwecwa kwesibili nokulinganisa;

- Ukuhlanganiswa kokuqala kwezithasiselo nezakhamzimba

- Yenza ukuxuba kwesibili kwempushana yobisi eluhlaza ngemva kokucwecwa kwesibili kanye nezithasiselo nezakhamzimba ngemva kokuhlanganisa kokuqala;

- Ukuze kuqinisekiswe ukufana kokuxuba, ukuxuba okwesithathu kwenziwa kamuva;

- Futhi wenze ukuhlolwa kwesampula kumpushana wobisi ngemuva kokuhlanganisa okwesithathu

- Ngemva kokudlula ukuhlolwa, ingena esiteji sokupakisha ngomtshina wensimbi ome mpo

Isinyathelo Sesithathu: Ukupakisha

Isiteji sokupakisha siyingxenye yengxenye yokusebenza yokuhlanza. Ngaphandle kokuhlangabezana nezidingo zesiteji sokuxuba, i-workshop kumele isebenzise umshini wokugcwalisa i-can othomathikhi evaliwe ukuze ulawule ngokuphumelelayo ukungcola kwesibili kokwenziwa.

Isiteji sokupakisha kulula ukusiqonda. Ngokuvamile, izinyathelo zokusebenza zimi kanje:

- Impushana exutshiwe ephumelele ukuhlolwa kwesinyathelo sesibili igcwaliswa ngokuzenzakalelayo futhi ipakishwe emathinini ngezinto zokupakisha ezifakwe inzalo.

- Ngemuva kokupakishwa, amathini ahanjiswa futhi afakwe ikhodi, futhi i-powder yobisi ekheniwe ikhethwa ngokungahleliwe ukuze ihlolwe. Amathini afanelekile afakwa emakhathoni futhi amabhokisi amakwe ngamakhodi.

- Ingabe impushana yobisi eqede zonke lezi zinyathelo ezingenhla ingangena esitolo bese ilinda ukulethwa

- Ukufaka ithini impushana yobisi emakhathoni

Okulandelayo uhlu lwemishini esetshenziswa ekuhlanganisweni okomile kobisi lwezinsana olusemathinini:

- Imishini yokungenisa umoya, kufaka phakathi isimo somoya esimaphakathi, izihlungi zomoya, amajeneretha e-ozone.

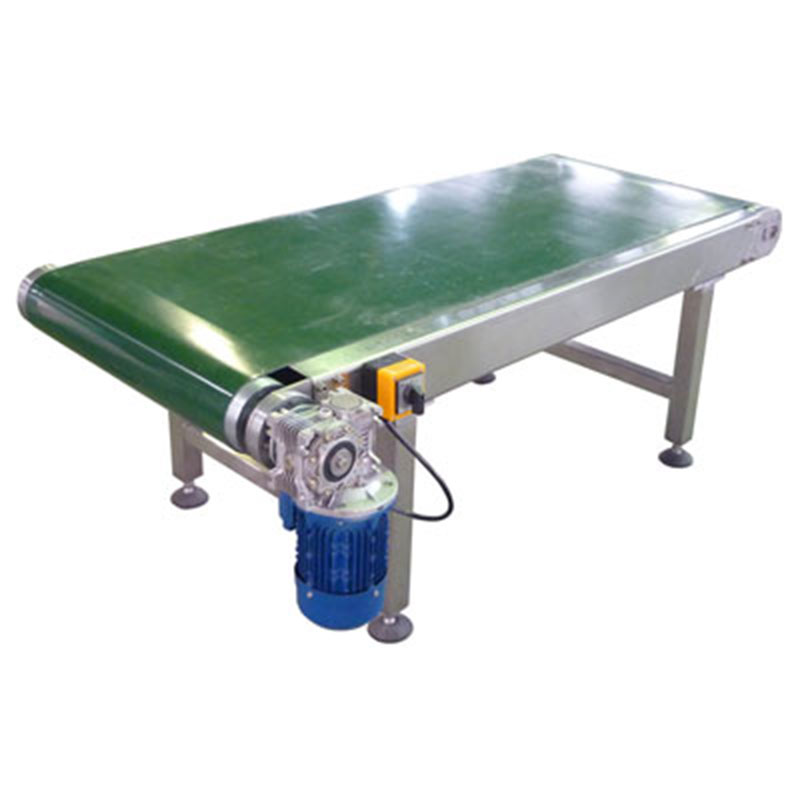

- Izinto zokusebenza zokudlulisa, okuhlanganisa izithutha zempushana, izinto zokuthutha amabhande , amaketango okuthutha, amafasitela okudlulisa avaliwe, namakheshi.

- Imishini yokwelapha kusengaphambili, okuhlanganisa inqola yothuli, isicoci sevacuum, isibulala magciwane kumhubhe.

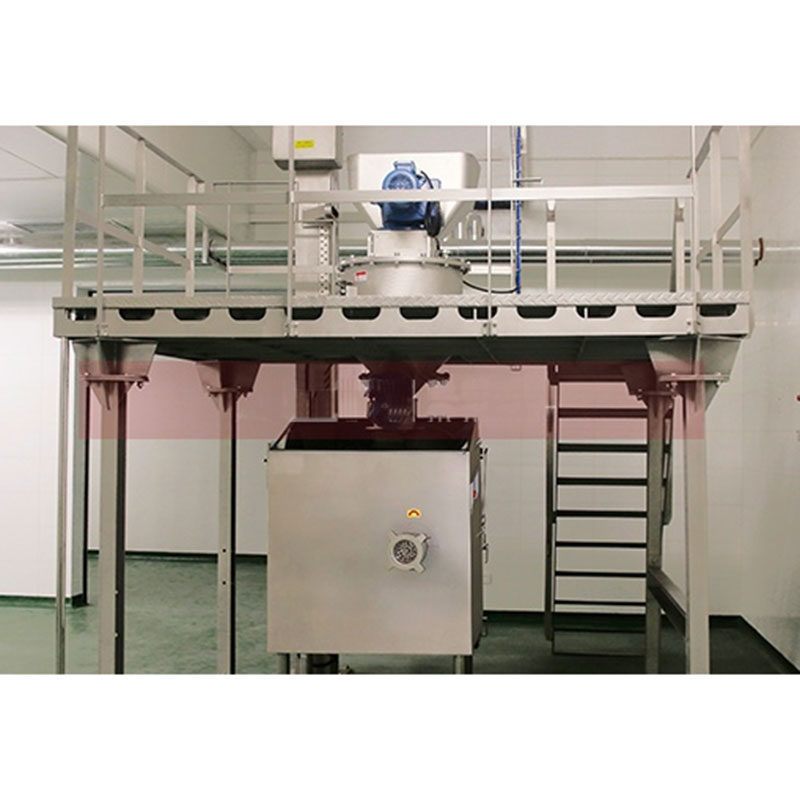

- Imishini yokuhlanganisa, okuhlanganisa iplatifomu yokusebenza, ishalofu, umshini wokuhlanganisa onezinhlangothi ezintathu, umxube ohlanganisa impushana eyomile

- Imishini yokupakisha, umshini wokugcwalisa we-othomathikhi, umshini we-capping, iphrinta ye-inkjet, ipulatifomu yokusebenza.

- Imishini yokulinganisa, izikali ze-elekthronikhi, izikali zokucindezela komoya, imishini yokulinganisa ezenzakalelayo yokugcwalisa amathini.

- Imishini yokugcina, amashalofu, ama-pallet, ama-forklift.

- Imishini yenhlanzeko, ikhabethe lokubulala amagciwane, umshini wokuwasha, ikhabethe lokubulala amagciwane izingubo zokusebenza, ishawa yomoya, ijeneretha ye-ozone, isifafazi sotshwala, umqoqi wothuli, i-dustbin, njll.

- Imishini yokuhlola, ibhalansi yokuhlaziya, ihhavini, i-centrifuge, isithando somlilo sikagesi, isihlungi sokungcola, idivayisi yokunquma amaprotheni, inkomba ye-insolubility index, i-fume hood, isibulala-magciwane esomile nesimanzi, ukugeza kwamanzi, njll.